Power control panels

Advantages

- Power control panels designed for industrial applications

- Quick and safe installation and start-up

- High-quality components (Eurotherm and Schneider Electric)

- Safety power contactor separated from the temperature control loop

- Optimized frame size for space saving

- Faster engineering time

Technical description

CETAL, industrial heating system designer and manufacturer, offers you a range of turn-key power control panels optimized for your process.

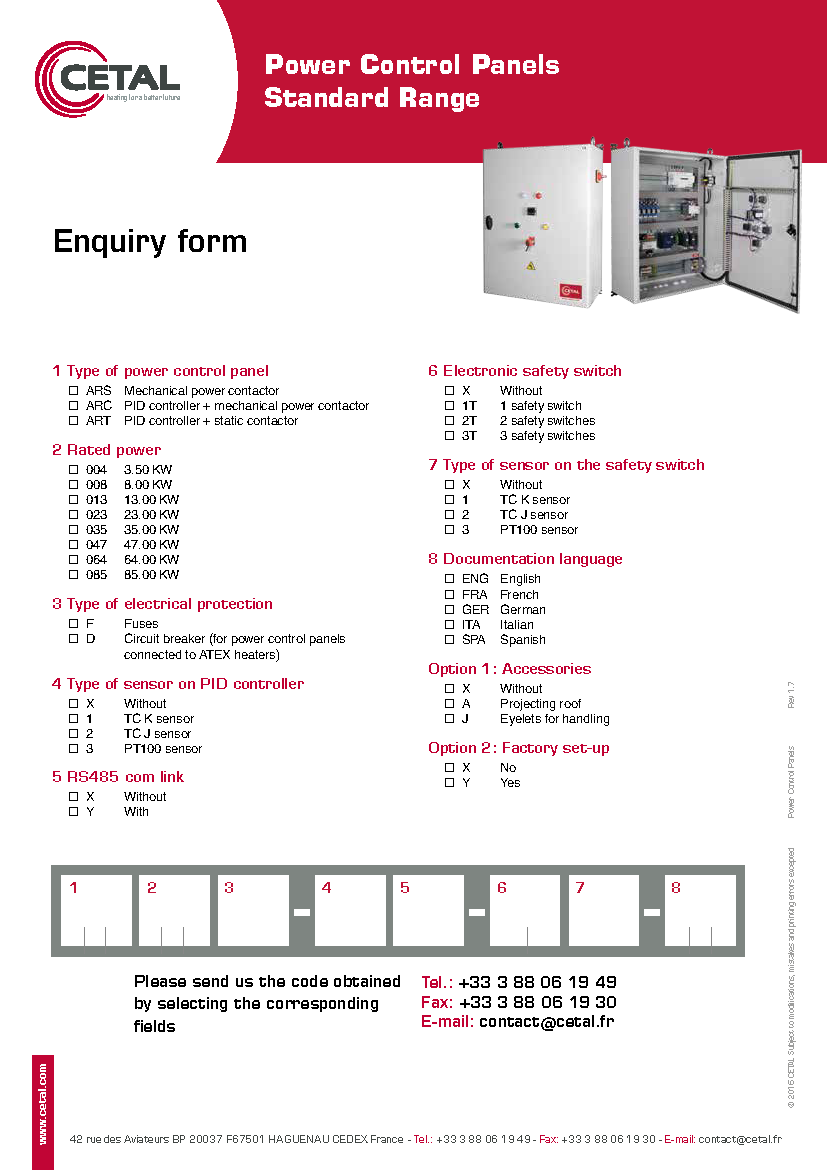

Which control mode to choose ?

For processes with high thermal inertia (for example, heating of large tanks of water or oil), a power control panel with On/Off control mode (TOR) with contactor (ARS or ARC models) is recommended.

PID (Proportional, Integral, and Derivative) controls are better suited:

- if the process consists in fast heating of liquid or gas (such as circulation heaters)

- if a quick reaction time with temperature control accuracy is required

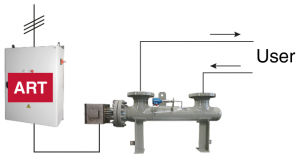

- and/if a variable flowrate is needed with power control through thyristor (ART model).

For use in

- Technical area

- Non-ATEX environment

ATEX power control panel or panels for outdoor use are available on request.

The power control panels are equiped with high-quality components (Eurotherm and Schneider Electric).

Inside the power control panel

- Main load break switch with external handle (lockable)

- Fuse disconnect switch + fuses

- 1 x safety power contactor

- External safety loop on terminals (ARC and ART models)

On front side

- On/Off illuminated green switch (ART model)

- White lamp (voltage on)

- Red lamp (global default)

- Reset pushbutton (ART model)

- Emergency stop pushbutton Technical data

- IP54 steel box

- Epoxy polyester surface, textured appearance 60 μm, colour Grey (RAL7035)

- 3-phase 400 V + earth (without neutral point)

- Safety transformer

- Power and dimensions see page 3

- Line safety contactor separated from temperature control loop

- The PID controllers and electronic thermostats are equipped with a factory-set measurementinput which can be reconfigured by the user:

- PT100 range from -200 to +200°C

- TC J, range from 0 to +450°C

- TC K, range from 0 to +1200°C

- Wall stand included

- Heating element connection through to terminal block, cable glands included

- Possibility to install remote emergency stop and On/Off switches

- Available information on any potential free terminal:

- On/Off status

- Globlal Default

- Emergency stop

All our power control panels comply with IEC‑EN‑61639 / IEC‑EN‑60364 / IEC‑EN 60204 standards and 2014/35/UE, CE directive (low voltage).

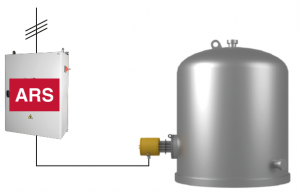

Mechanical contactor associated with electromechanical thermostat (On/Off) and/or external overtemperature controller

|

Reference |

Max. rated power (KW) |

Dimensions (mm) |

Weight |

||

|

Height |

Width |

Depth |

(Kg) |

||

|

ARS 004 |

3.5 |

400 |

300 |

200 |

10 |

|

ARS 008 |

8.00 |

400 |

300 |

200 |

10 |

|

ARS 013 |

13.00 |

400 |

300 |

200 |

12 |

|

ARS 023 |

23.00 |

500 |

300 |

200 |

18 |

|

ARS 035 |

35.00 |

600 |

500 |

250 |

35 |

|

ARS 047 |

47.00 |

600 |

500 |

250 |

40 |

|

ARS 064 |

64.00 |

600 |

500 |

250 |

45 |

|

ARS 085 |

85.00 |

800 |

600 |

250 |

50 |

Tank, storage

Example: Hot-water tank

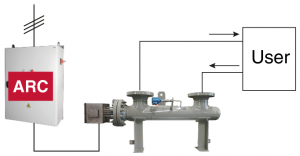

Mechanical power contactor associated with self-tuning PID controller

|

Reference |

Max. rated power (KW) |

Dimensions (mm) |

Weight |

||

|

Height |

Width |

Depth |

(Kg) |

||

|

ARC 004 |

3.5 |

600 |

500 |

200 |

25 |

|

ARC 008 |

8.00 |

600 |

500 |

200 |

35 |

|

ARC 013 |

13.00 |

600 |

500 |

200 |

35 |

|

ARC 023 |

23.00 |

600 |

500 |

200 |

38 |

|

ARC 035 |

35.00 |

600 |

500 |

250 |

38 |

|

ARC 047 |

47.00 |

600 |

500 |

250 |

42 |

|

ARC 064 |

64.00 |

600 |

500 |

250 |

55 |

|

ARC 085 |

85.00 |

800 |

600 |

250 |

55 |

Application with high inertia

(closed loop)

Example: Water or thermal fluid heating

Static contactor (Thyristor) associated with self-tuning PID controller

|

Reference |

Max. rated power (KW) |

Dimensions (mm) |

Weight |

||

|

Height |

Width |

Depth |

(Kg) |

||

|

ART 004 |

3.5 |

600 |

500 |

200 |

25 |

|

ART 008 |

8.00 |

600 |

500 |

200 |

35 |

|

ART 013 |

13.00 |

600 |

500 |

250 |

35 |

|

ART 023 |

23.00 |

600 |

500 |

250 |

38 |

|

ART 035 |

35.00 |

600 |

600 |

300 |

38 |

|

ART 047 |

47.00 |

600 |

600 |

300 |

42 |

|

ART 064 |

64.00 |

1000 |

600 |

300 |

75 |

|

ART 085 |

85.00 |

1000 |

600 |

400 |

90 |

Application with low inertia

(open loop)

Example: Gas circulation heater or sensitive fluid heating

Options

For all models

- Projecting roof or eyelet for handling

For ARC and ART model

- External safety loop on terminals

- Electronic thermostat security controller

- 2-wire RS485 com link on PID controller

For power control panels connected to ATEX heaters: 30 mA circuit breaker