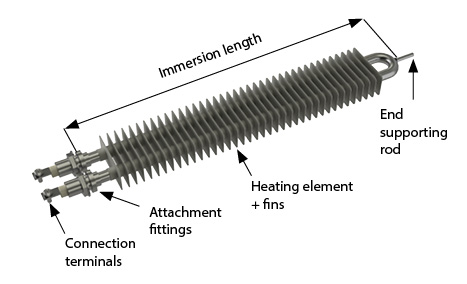

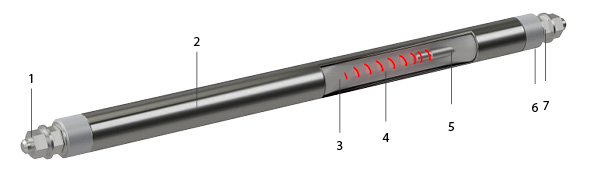

Customized ribbed heating elements

Product overview

- Power from 200 W – 10 kW or more

- Tubular heating elements in AISI 321 stainless steel equipped with zinc-coated fins

- Rectangular or round fins

- Mounting with crimped steel connector

- U-shaped terminals

- Well-designed for premises air heating or gas heating in natural or forced circulation

- Max. sheath tube temperature:

- 350°C for steel fins

- 600°C for stainless steel fins (option)

- Used for exemple in duct heaters

Advantages

- Reliability and robustness of the heating element. High-quality raw material.

- Different types of fins : rectangular, round, spiral fins

Operating conditions

- Hazardous areas (ATEX/IECEx) and NEC 505

- Onshore / offshore environment

Gas

- Air, max load 0.1 – 8W/cm² acc to sheath temp, material: 321 and speed (m/s)

- Non-corrosive gas

Technical description

The watt density, tube diameter and the tube sheath are chosen to optimize the reliability and robustness (corrosion, temperature) of CETAL equipments.

Technologies

- Tubular heating element

Tube diameter & material

- Tube diameter: 8.5 / 10 / 13,5 / 16 mm

- Tube material: Stainless steel AISI 304 or 321

- Tube type: sealed tube

Manufacturing

- 100% of the components come high quality supplier from Europe

- 100% manufacture within CETAL factory

- Connection terminals

- Tube

- Insulation : magnesia oxyde (Mg O), to secure optimized heat transfer and electrical insulation.

- Resistance wire: Made of Nickel Chrome 80/20, it is the active part of the heating element (Joule effect)

- Cold length

- Sealing material: Keeps out external moisture. Different types (silicon, resins, cement) are used depending on the industrial application, the external medium and temperature

- Output insulation: Made of steatite ou corundum, it provides dielectric insulation (creepage distance, distance in the air).

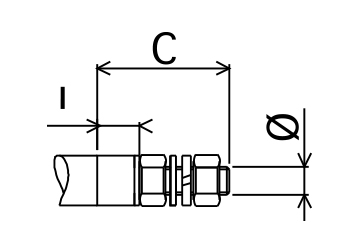

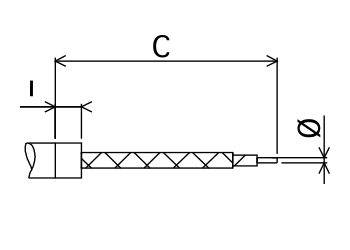

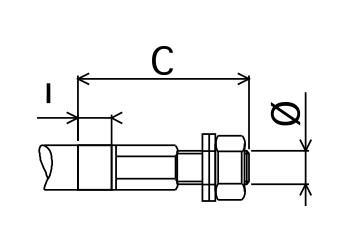

Type B 100

- THREADED STEEL OR STAINLESS STEEL ROD

| Dimensions | Sheaths Ø | ||||||

| Ø mm | C | I | 6.5 | 8.5 | 10 | 13.5 | 16 |

| M4 x 0.7 | 20 | 5 | |||||

| M4 x 0.7 | 20 | 5 | |||||

| M4 x 0.7 | 20 | 5 | |||||

| M5 x 0.8 | 30 | 10 | |||||

| M5 x 0.8 | 30 | 10 | |||||

| M6 x 1 | 35 | 10 | |||||

| M6 x 1 | 35 | 10 | |||||

| M8 x 1.25 | 35 | 10 | |||||

| M8 x 1.25 | 35 | 10 | |||||

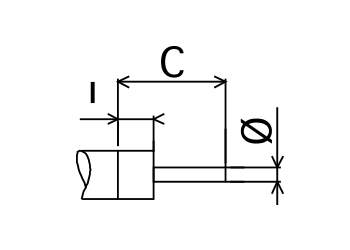

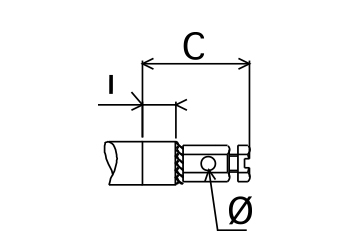

Type B 200

- PLAIN ROD

| Dimensions | Sheaths Ø | ||||||

| Ø mm | C | I | 6.5 | 8.5 | 10 | 13.5 | 16 |

| 2 | 20 | 5 | |||||

| 3.5 | 25 | 5 | |||||

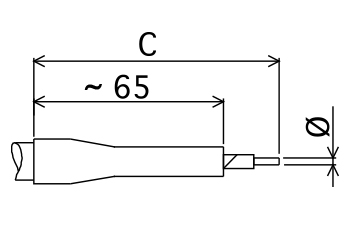

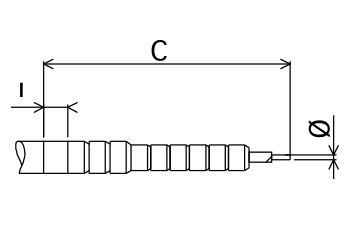

Type B 300

- BRAID OR CABLE

| Dimensions | Sheaths Ø | |||||

| section mm² | C | 6.5 | 8.5 | 10 | 13.5 | 16 |

| PVC INSOLATED COPPER CABLE H07VK 70°C | ||||||

| 1.5 | (1) | |||||

| 2.5 | (1) | |||||

| RUBBER INSOLATED COPPER H07RNF 85°C | ||||||

| 1.5 | (1) | |||||

| 2.5 | (1) | |||||

| 4 | (1) | |||||

| 1.5 | (1) | |||||

| 2.5 | (1) | |||||

| 4 | (1) | |||||

| 6 | (1) | |||||

| 10 | (1) | |||||

| SILICONE INSOLATED COPPER 180°C | ||||||

| 1.5 | (1) | |||||

| 2.5 | (1) | |||||

| 4 | (1) | |||||

| 6 | (1) | |||||

| GLASS BRAIDED COPPER 280°C | ||||||

| 1 | (1) | |||||

| 1.5 | (1) | |||||

| 2.5 | (1) | |||||

| 4 | (1) | |||||

| 6 | (1) | |||||

| INSOLATED NICKEL WIRE 700°C | ||||||

| 1.5 | (1) | |||||

| 2.5 | (1) | |||||

| 4 | (1) | |||||

| 6 | (1) | |||||

(1) Cable lenght go request

| Dimensions | Sheaths Ø | |||||

| section mm² | C | 6.5 | 8.5 | 10 | 13.5 | 16 |

| NICKEL BRAIDED NICKEL 350°C / 450°C | ||||||

| 1 | (1) | |||||

| 2.5 | (1) | |||||

| 2.5 | (1) | |||||

| 4 | (1) | |||||

| 6 | (1) | |||||

(1) Cable lenght go request

| Dimensions | Sheaths Ø | |||||

| section mm² | C | 6.5 | 8.5 | 10 | 13.5 | 16 |

| CERAMIC NICKEL WIRE | ||||||

| 1.5 | (1) | |||||

| 2.5 | (1) | |||||

(1) Cable lenght go request

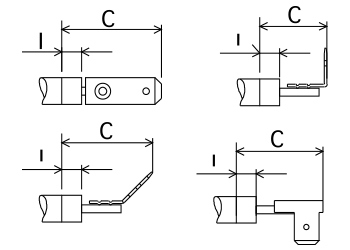

Type B 400

- 6,35 TAB

| Dimensions | Sheaths Ø | ||||

| Description | C | I | 6.5 | 8.5 | 10 |

| Straight single | 25 | 5 | |||

| carved single | 23 | 5 | |||

| Transverse single | 15 | 5 | |||

| Straight twin | 22 | 5 | |||

| Delta twin | 22 | 5 | |||

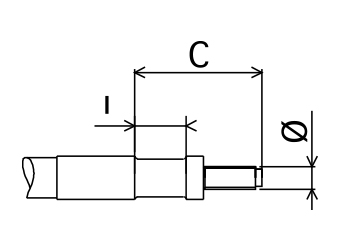

Type B 500

- FLAT TERMINAL

| Dimensions | Sheaths Ø | |||||

| C | I | 6.5 | 8.5 | 10 | 13.5 | 16 |

| 25 | 5 | |||||

| 30 | 10 | |||||

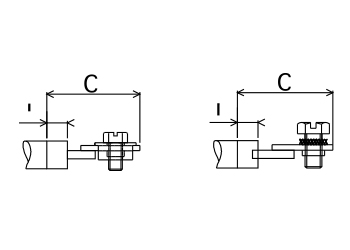

Type B 600

- THREADED TERMINAL

| Code | Dimensions | Sheaths Ø | ||||

| Ø mm | C | I | 6.5 | 8.5 | 10 | |

| LAITON : B 614-6 | M6 x 1 | 30 | 5 | |||

| INOX : B 623-6 | M6 x 1 | 21 | 5 | |||

Type B 700

- SCREW TYPE BRASS TERMINAL

| Dimensions | Sheaths Ø | |||

| C | I | 6.5 | 8.5 | 10 |

| 15 | 5 | |||

Type B 800

- BRAZABLE STEATITE

| Dimensions | Sheaths Ø | ||||||

| Ø mm | C | I | 6.5 | 8.5 | 10 | 13.5 | 16 |

| M 6 | 37 | 13 | |||||

| M 6 | 37 | 13 | |||||

| M 8 | 55 | 15 | |||||

| Use in humid conditions | watertight | ||||||

| temperature from – 60°C to + 200°C | |||||||

| defrosting resistance | |||||||

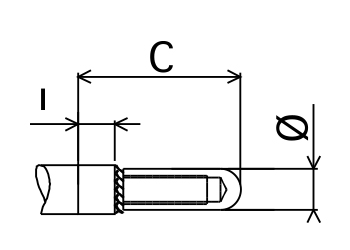

Type B 900

- BRASS PIN TERMINAL

| Dimensions | Sheaths Ø | ||||||

| Ø mm | C | I | 6.5 | 8.5 | 10 | 13.5 | 16 |

| 6 | 22 | 5 | |||||

| 6 | 22 | 5 | |||||

- Rectangular fins:

- tube diameter 8,5 & 10 mm: 50×25 mm in steel, zinc coated or stainless steel

- tube diameter 13,5 & 16 mm: 80×40 mm in steel, zinc coated or stainless steel

- Round fins:

- tube diameter 8,5 & 10 mm: 24 mm in zinc coated or stainless steel

- tube diameter 10 mm: 24 mm in stainless steel

- tube diameter 16 mm: 40 mm in zinc coated or stainless steel

- Spiral round fins:

- tube diameter 10 mm: 26 mm in stainless steel AISI 430

- The fins are fitted without clearance with the zinc coated or stainless steel fins

- Crimped or welded steel, stainless steel connectors

- Supply with washer and nuts

- According to CE European directives and CE market (for Europe)

- ATEX/IECEx certificate for component or system

- EAC CU TR, c CSA us (NEC 505)

![]()

Electrical tests

- Power test by cold resistance measurement. Allowed tolerance: -5% and +10% of the nominal resistance value.

- Insulation test, direct voltage 500V, mini cold value is > 100 Megohms

- Dielectric test, 2U + 1000V

- The stray current and the hot dielectric rigidity can be measured on a sample at operating temperature (on request).

100% of the heating elements are tested before shipment (final control)

Mechanical tests

- Visual inspection

Dimensional test

- Critical dimensions are tested