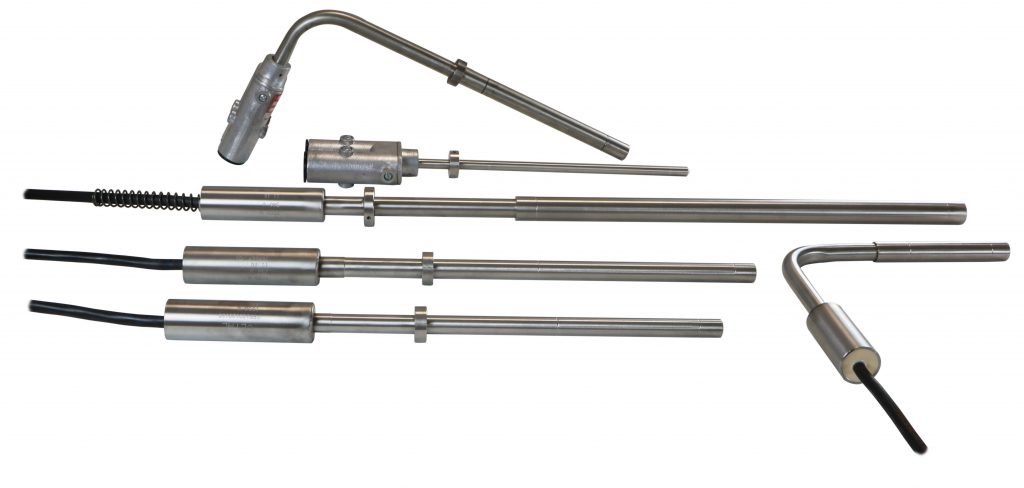

High-flux bolt heaters

Product overview

- Power up to 10kW (higher on request)

- Watt density up to 40 W/cm² (To be checked)

- Voltage max. 690 V

Advantages

- Very short heating time

- Heating to approx. 350 °C (depending on the bolt material)

- Easy handling

- One operator per machine

- One power outlet per bolt heater

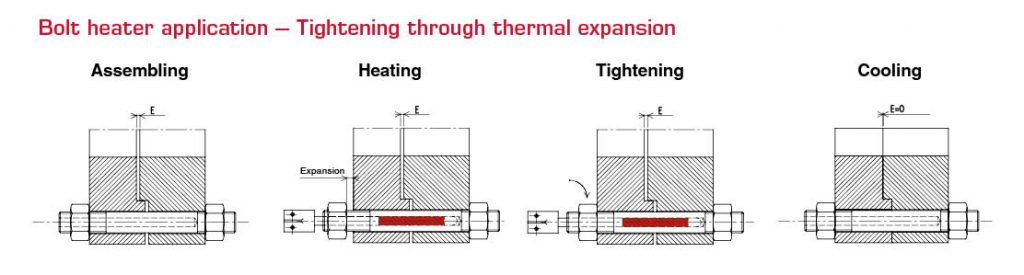

- Significantly reduces the assembling/deassembling time of large forged and cast-iron parts

- Capacity to heat only the central part of the bolt

- Long lifetime: 10 000 cycles

- Workstation safety through low voltage < 50 V

Operating conditions

- Normal (non-ATEX)

- Hazardous areas (ATEX/IECEx) and NEC 505

Solids

- Steel / Stainess steel bolts

Technical description

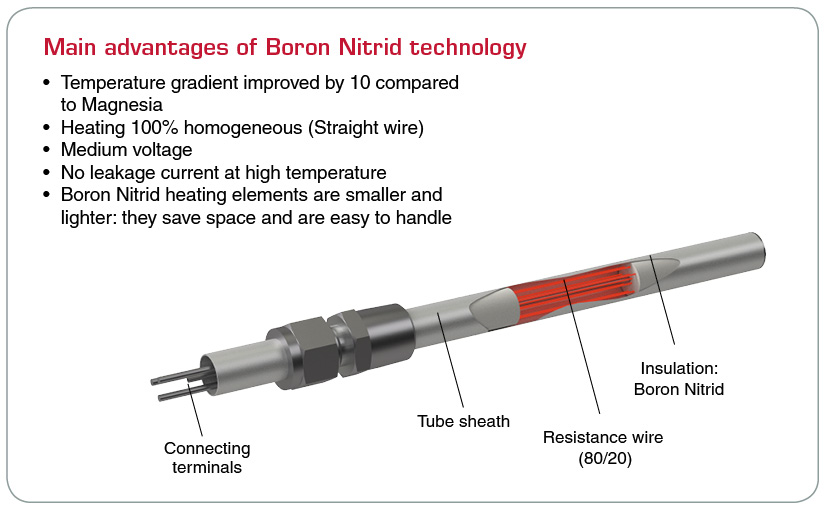

High performance through boron nitrid insulation

The use of boron nitrid as insulation allows to concentrate a lot of energy in a small space. The power is transmitted by radiation.

With this technology, high temperatures can be obtained in a short time, thus reducing to a few minutes the nut tightening/untightening time.

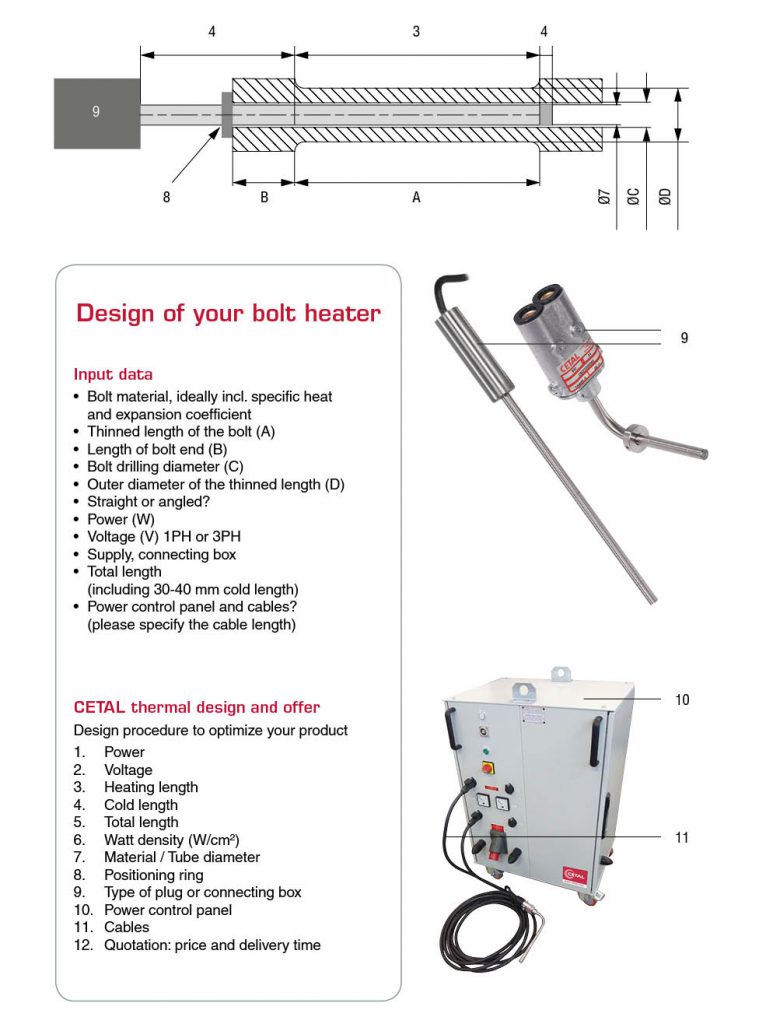

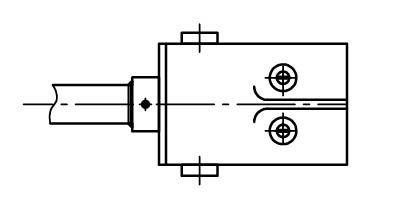

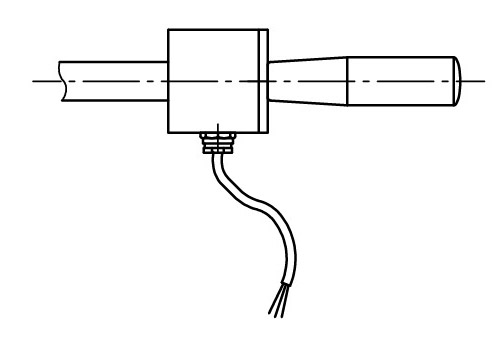

Design

The bolt heaters are designed according to specifications using standard tube diameters.

Lenght and power are defined according to the bolt to be heated (size, Ø of drilling, mounting tolerance).

The bolt heaters can be supplied with 24 V (BT plug), 110 V, 230 V or other voltage.

The heating part of the bolt heaters is indicated through small machined grooves. To avoid incorrect installation, a positioning ring helps identifying the active zone.

CETAL expertise

After customer specification analysis, our engineers will drive you to the best solution for your process.

Tube material

- Inox AISI 316L (1.4404)

- Others on request

Tube / bolt diameters (mm)

|

Ø bolt heater |

Ø H11 bolt |

|---|---|

|

10.7 |

11 |

|

11.7 |

12 |

|

12.2 |

12.5 |

|

15.7 |

16 |

|

17.7 |

18 |

|

19.7 |

20 |

|

21.65 |

22 |

|

24.6 |

25 |

|

25.6 |

26 |

|

29.6 |

30 |

Other diameters on request

Connection / Connection box

- 24 V or 48 V plug

- Female aluminum plug

- Male plug, plastic, with cable

- Thermal grease

- Box filled with resin, 230-400 V

- With HO7RNF or silicone cable

- Thermal grease

- Box with handle, 230-400 V

- With or without LED

- With HO7RNF or silicone cable

- Thermal grease

- Other connection boxes on request

(e. g, RATEAU connection box), can be supplied with simple threaded rods

- Temperature sensors (thermostat, limiter, thermocouple or PT100) in the medium (process control) or on theheating element (safety control), on the flange or in the connecting box.

- Voltage: VAC or VCC

- Cabling according to main voltage VAC/VCC 1PH + N or 3PH

- Power: < 10 000 W (higher on request)

- Standard documentation

- EU Certificate of Compliance

- Instruction manual

- On-request documentation

- Certificate of conformity to the order

- Supplied according to directives and standard

- Material certificate 3.1 according to NF EN 10204

- According to standard to comply with

- EAC CU&TR

![]()

- Detachable cable (except for box filled with resin)

- Other connection boxes on request

- Power control panels

- Power 5, 10, 15, 20 KVA

- 24 V / 48 V, primary 230 V or 400 V

- 110 V / 230 V on request