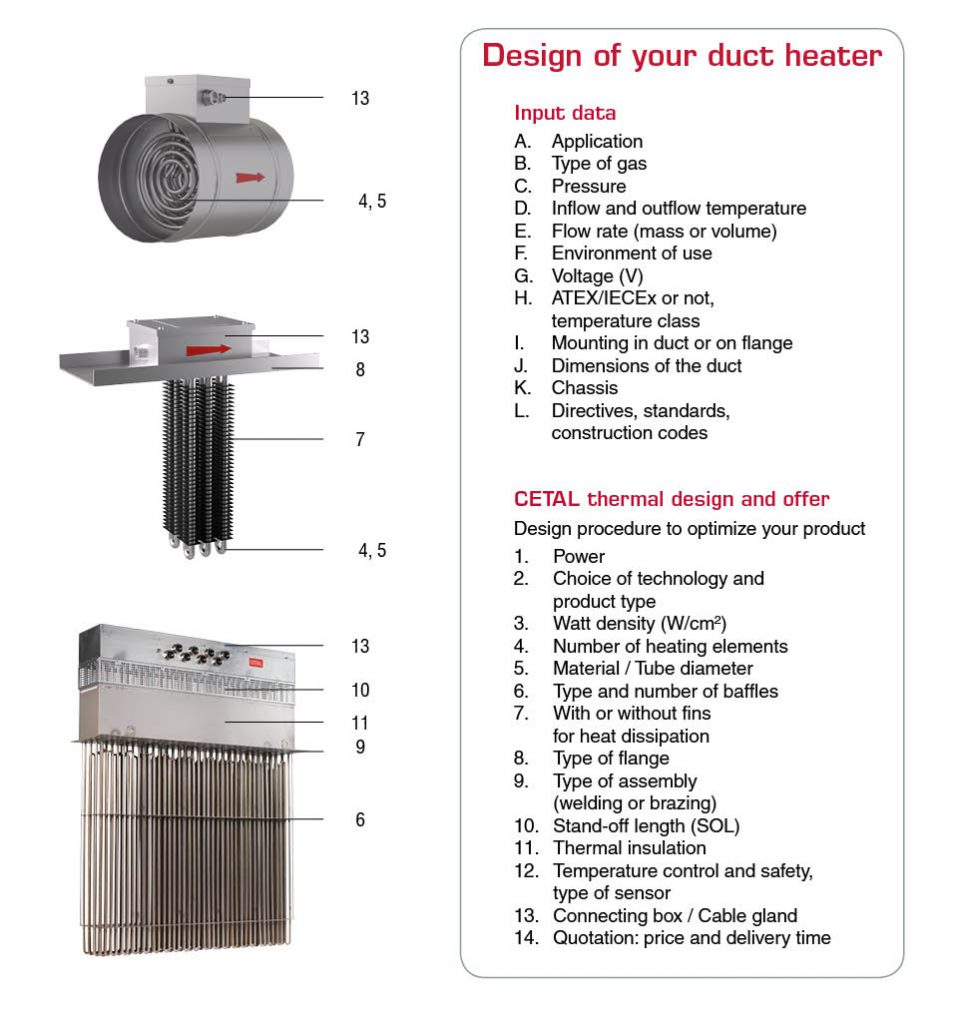

Customized duct heaters

Product overview

- Power from 1kW to 1MW

- Watt density from 0.1 to 8W/cm²

- Process temperature up to +700 °C

- Voltage max. 690 V

- Recommended minimum air speed is 2 m/s.

- Electrical wiring is done in a protected steel or stainless steel connecting box.

- Vertical or horizontal position

Advantages

- Large range of materials and options according to customer process and conditions of use

- Benefit from CETAL’s 50 years of experience as designer and manufacturer!

- Equipment available for use in hazardous areas or safe environment

- The end-to-end control of the design and production chain allows us to deliver a product which suits your process perfectly

- Available design enabling to remove and replace the heating element for lifetime & cost optimization

Operating conditions

- Normal (non-ATEX)

- Hazardous areas (ATEX/IECEx) and NEC 505

- Extreme environments: – 60°C to + 80 °C

- Onshore / Offshore environment

- Salt atmosphere

- Vertical or horizontal mounting

Gas

- Air, max load 0.1 – 8W/cm² acc to sheath temp, material: 321

- Circulating air, max load 0.1 – 8 W/cm² acc to sheath temp, material: 309

Technical description

The watt density, tube diameter and the tube sheath are chosen to optimize the reliability and robustness (corrosion, temperature) of CETAL equipments.

Technologies

- Tubular heating element

Tube diameter & material

- Tube diameter: 6.5 / 8.5 / 10 / 13.5 / 16 mm

- Tube material:

- Stainless steel: AISI 321 (1.4541) / AISI 316L (1.4404) / AISI 309 (1.4828)

- Others: Incoloy 800 (1.4876) / Incoloy 825 (2.4858) / Inconel 600 (2.4816)

- Specific coating: TeflonTM (PTFE) / Halar

- Tube type: sealed tube, seamless tube (on request)

Manufacturing

- 100% of the components come from high-quality suppliers from Europe

- 100% manufacturing in CETAL factory

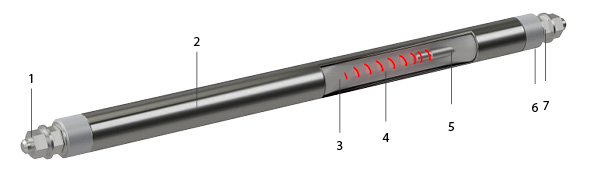

- Connection terminals

- Tube

- Insulation : magnesia oxyde (Mg O), to secure optimized heat transfer and electrical insulation.

- Resistance wire: Made of Nickel Chrome 80/20, it is the active part of the heating element (Joule effect)

- Cold length

- Sealing material: Keeps out external moisture. Different types (silicon, resins, cement) are used depending on the industrialapplication, the external medium and temperature.

- Output insulation: Made of steatite ou corundum, it provides dielectric insulation (creepage distance, distance in the air).

- Heating elements mounted on a galvanized or stainless steel plate

- Shape according to specifications

- Heating elements mounted thanks to connector (screwed or brazed) or welding on the plate

- Non ATEX connecting box

- IP 54 / IP 66 / IP 67

- Material: painted steel, stainless steel, aluminium

- Polyamide or nickel-plated

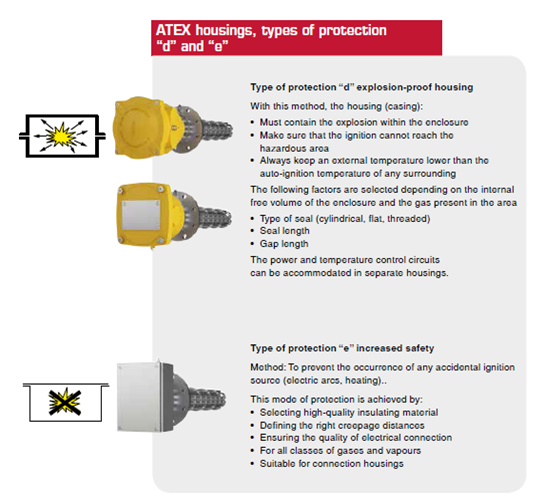

- ATEX/IECEx connecting box

- Explosion-proof connecting box, aluminium, stainless steel or painted steel, Ex d IIC

- Stainless steel increased security enclosure,Ex e IIC

- Nickel-plated brass cable gland (stainless steel as option)

- Fluid temperature <110°C, no offset

- Fluid temperature >110°C, offset between the protecting box and the tank is recommended

- Temperature sensors (thermostat, limiter, thermocouple or PT100) in the medium (process control) or on the heating element (safety control), on the flange or in the connecting box.

- Voltage: VAC or VCC

- Cabling according to main voltage VAC/VCC 1PH + N or 3PH

- Power : a few Watt to several Megawatts

- Standard documentation

- Certificate of conformity to the order

- Heater wiring diagram

- Instruction manual

- On-request documentation

- Supplied according to directives, standard and construction code

- Welder qualifications (QS)

- Welding qualifications (QMOS)

- Material certificate 3.1 acc. to NF EN 10204

- According to CE European directives and CE market (for Europe)

- ATEX/IECEx certificate for component or system

- EAC CU TR, c CSA us (NEC 505)

![]()

Electrical tests

- Power test by cold resistance measurement. Allowed tolerance: -5% and +10% of the nominal resistance value.

- Insulationtest, direct voltage 500 V, mini cold value is > 100 Megohms

- Dielectric test, (2U + 1000 V) x 1,2 during 1 second

- The stray current and the hot dielectric rigidity can be measured on a sample at operating temperature (on request).

- 100% of the heating elements are tested before shipment (Final control)

Mechanical tests

- Visual inspection

- X-ray test (if required)

- Liquid penetrant test

Dimensional test

- Critical dimensions are tested

Other tests / operations

- Helium test (on request)

- Degreasing

- Argon cleaning

Third party

- Third party inspection (on request)

- Temperature control : Temperature sensors (thermostat, limiter, thermocouple or PT100) in the medium (process control) or on the heating element (safety control), on the flange or in the connecting box.

- Separate connecting box for temperature control out of the power connecting box

- Stainless steel material for ATEX/IECEx cable gland

- Space heaters against moisture inside the connecting box

- Coating for the connecting box customized specifications and colors

- Tropicalization: Adapted materials and components, heat-shrink insulated terminals, for extreme atmospheres (moisture, temperature)

- Insulation: according to design if needed

Standard power control panels CETAL offers a large range of cost-effective power control panels.

Standard power control panels CETAL offers a large range of cost-effective power control panels.

In addition to heater design, the use of specifically developed connection boxes allows to install the products in hazardous areas.

The increased safety protection mode “e” (EN60079-7) or the explosion-proof protection mode “d” (EN 60079-1), together with temperature control acc. to EN 60079-0, make it possible to operate the equipments in hazardous area (zone 1 and zone 2) for gases of the A-B-C groups.