About Us

The CETAL project

CETAL Clean Flexible Heating Technology for a Better World

Because we believe heat is one of the cleanest and best energies for industrial use. Every day, we strive to tailor our technology and knowhow to design ever more efficient heating systems and solutions for your needs.

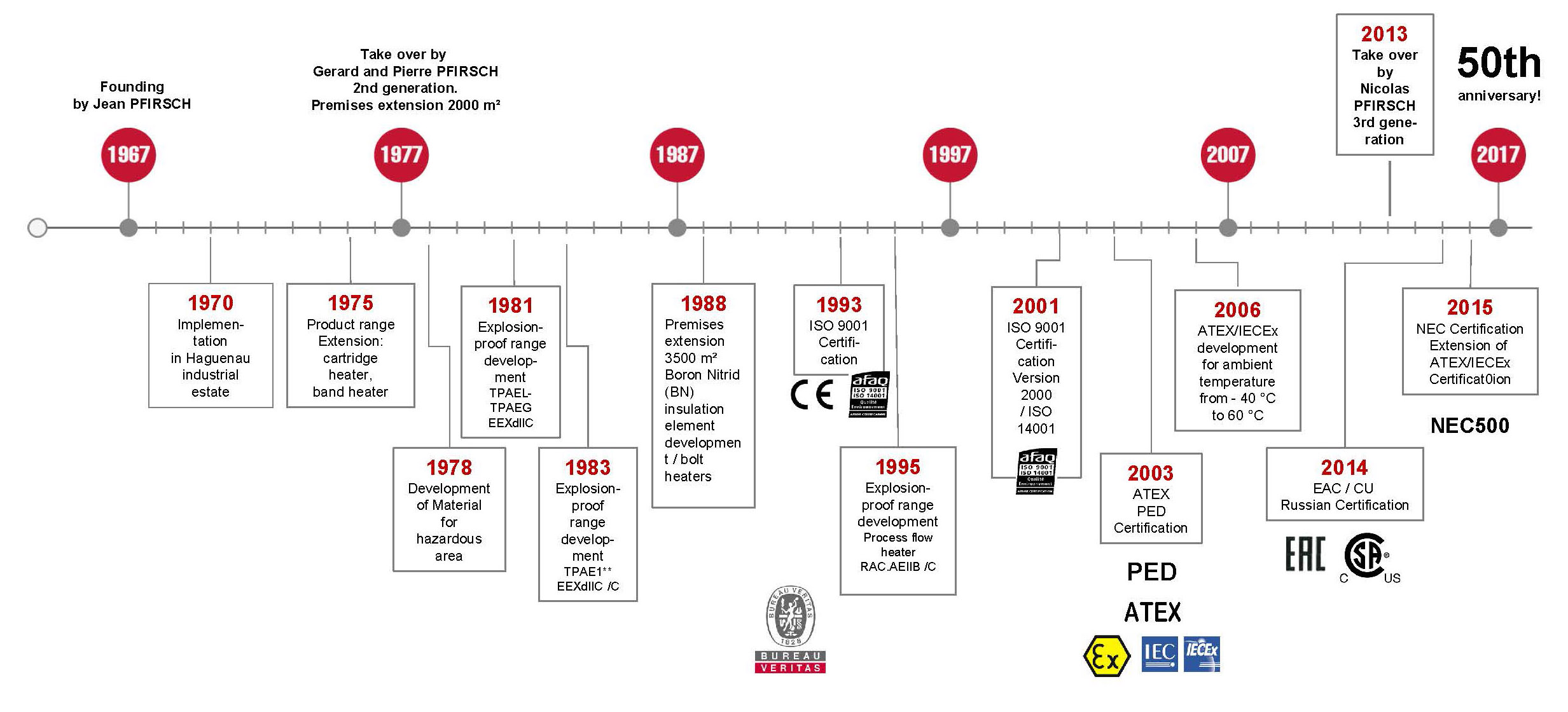

Since 1967, through experience and R&D, we have been improving our customized heating element, the key component for making your process more efficient and durable. This gives you the power in your process to heat and meet your needs, thereby ensuring a safer and more sustainable environment and a more efficient and innovative industry.

For us, just like heat exchange, sharing and exchanging information between people has always been the main factor for understanding issues at an early stage to efficiently enhance performance. At CETAL, there is this extra warmth in our team spirit which includes an open and caring special relationship with our customers.

Together we are an unbeatable team, clear understanding of your requirements, clear sharing of issues and clear definition of the best and most efficient solutions quickly.

Proud in our beliefs, we focus our attention on selectively applying our technology, knowhow and reliability, with the goal to bringing heat efficiently to the world where it is needed, without heating up the planet, for a better world.

CETAL strenghts

- CETAL has built a solid experience over 50 years

- No compromise on quality & safety

- Technical competence & tools, ability to design the best solutions for our customers

- Empowered people looking for delivering the best value for our customers

- High-quality supplier base (from Europe only)

- 100% of the heating elements produced in our factory.

- Lean approach

- CETAL 4.0, looking for innovation and value increase

- Responsiveness in case of urgency such as production stop (very short delivery time)

- Solid financial situation and sustainability

Technologies and operating conditions

Technologies

- Magnesium oxyde insulation

- Boron nitrid insulation (18 to 150 W/cm²), high flux, very high performance (VHP)

- Induction

- Ceramic

- Infrared

Technologies and operating conditions

Operating conditions

- Normal (non-ATEX)

- Hazardous areas (ATEX/IECEx)

- Extreme environments: – 60°C to + 80 °C

- Fluid/solid: from – 270 °C (3 K) to 1000 °C

- Onshore / Offshore environment

- Helium testing

- Pressure: 250 bars